What to Look for in a Gastro Molding Consumables Manufacturer

Choosing the right partner for medical consumables begins with evaluating the source. A premier Gastro Molding Consumables manufacturer distinguishes itself through an unwavering commitment to quality and innovation. This commitment is evident in every stage of production, from the selection of raw materials to the final quality assurance checks. The use of premium, medical-grade plastics is non-negotiable, as these materials must guarantee biocompatibility and structural integrity under rigorous clinical conditions. Furthermore, a leading manufacturer invests heavily in precision engineering, ensuring that every adapter, connector, and valve functions flawlessly. This meticulous attention to detail minimizes risks such as leaks, contamination, or connection failures, which could have serious implications for patient outcomes. The ability to innovate and respond to the evolving needs of the medical community is another hallmark of a top-tier manufacturer, one who continuously refines its designs to enhance usability and safety.

The Importance of a dependable Gastro Molding Consumables Supplier

Beyond manufacturing excellence, the reliability of your supply chain is equally crucial. A dependable Gastro Molding Consumables supplier acts as a strategic partner to healthcare facilities, not just a vendor. Their role is to ensure a consistent and uninterrupted flow of essential products, preventing a a shortage that could disrupt patient care schedules and operational efficiency. A trustworthy supplier maintains a robust quality control system, verifying that every batch of products meets stringent medical standards before it reaches the client. They provide transparent communication, responsive customer service, and logistical expertise to manage inventory effectively. By partnering with a reliable Gastro Molding Consumables supplier, medical institutions can streamline their procurement processes, reduce administrative burdens, and have confidence that they will always have the high-quality consumables they need to serve their patients.

Advancing Gastroenterology with Innovative OEM Gastro Molding Consumables

Innovation in medical consumables is driven by a deep understanding of clinical workflows and challenges. The latest generation of OEM Gastro Molding Consumables incorporates thoughtful design features that directly address the needs of healthcare professionals. A central component, such as a precision-engineered three-way stopcock with a rotating valve, is essential for precise fluid control. This allows clinicians to switch between multiple fluid lines effortlessly and securely, enhancing both efficiency and patient safety by reducing the need for frequent reconnections. Similarly, features like specialized caps and locks that guarantee a secure fit are vital for minimizing the risk of leaks or microbial contamination. Adaptable split septums and other versatile fittings further accentuate the flexibility of these components, allowing for seamless integration into a wide variety of medical protocols and equipment setups. These advancements are not merely incremental improvements; they represent a significant step forward in making medical procedures safer and more efficient.

Design Philosophy: Where Functionality Meets User-Centric Design

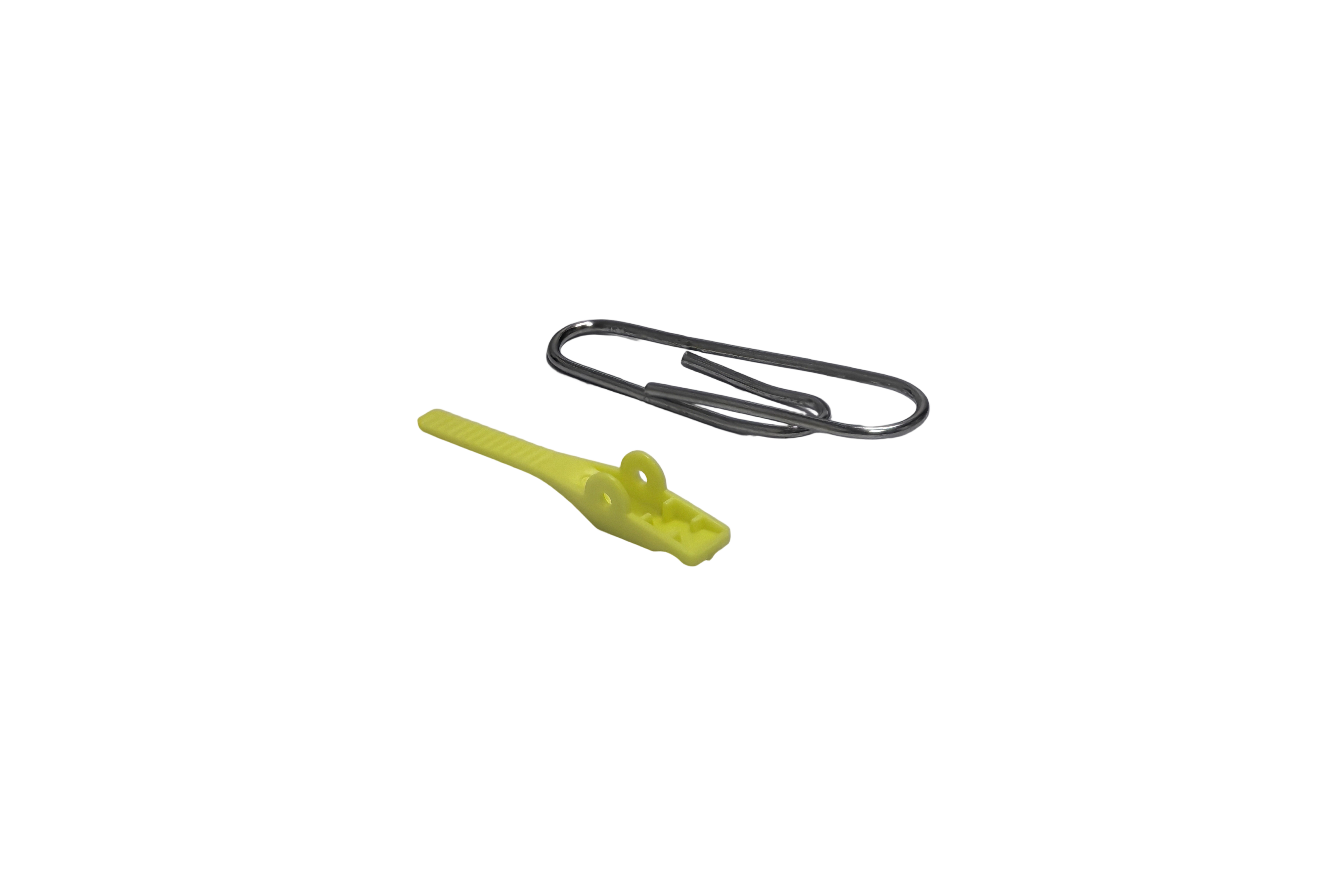

Effective medical device design extends beyond technical specifications; it encompasses the human element. The best OEM Gastro Molding Consumables are developed with a user-centric philosophy, focusing on ease of use in high-stress clinical environments. Thoughtful details, such as the use of distinct colors like soothing blue, pristine translucent, and a vibrant green, serve a practical purpose. Color-coding allows for swift identification and differentiation of components, reducing the cognitive load on medical staff during fast-paced procedures. Ergonomics also play a vital role. For example, an ergonomically designed grip handle ensures easy and secure handling when adjusting connectors or valves, which is especially critical in scenarios where quick alterations are necessary. This focus on intuitive design demonstrates a manufacturer's commitment to not only patient safety but also the well-being and efficiency of the healthcare providers who use their products daily.

Tengfeng Medical Technology: Your Trusted Partner in Medical Consumables

At Tengfeng Medical Technology Co., Ltd, we embody the principles of a leading-edge innovator and a reliable partner. As an experienced Gastro Molding Consumables manufacturer, we are dedicated to pushing the boundaries of what's possible in medical component design. Our versatile and elegantly designed connection and control components are a testament to our legacy of precision and quality. We also pride ourselves on being a dependable Gastro Molding Consumables supplier, ensuring that our partners in healthcare have access to the state-of-the-art tools they need. Our commitment is simple: to enhance healthcare delivery by providing solutions that are built on a foundation of reliability and functionality. By choosing Tengfeng Med, healthcare facilities are not just purchasing products; they are investing in a partnership dedicated to excellence.

Choosing the Right Partner for Your Medical Consumable Needs

Ultimately, the choice of a consumables provider has a direct impact on the quality of patient care. Selecting a partner who excels in both manufacturing and supply ensures that your facility is equipped with the best tools available. The future of seamless medical integration depends on expertly engineered, user-friendly, and reliable components. By prioritizing innovative and high-quality OEM Gastro Molding Consumables, healthcare providers can empower their teams to focus on what truly matters: delivering exceptional care and achieving the best possible patient outcomes. Embrace the future of medical technology with a partner committed to innovation, precision, and unwavering quality.