The Strategic Advantage of Choosing an OEM Partner

For medical device companies, partnering with an Original Equipment Manufacturer (OEM) offers a significant strategic advantage. It allows them to bypass the immense capital investment and operational complexities associated with setting up and running a specialized manufacturing facility. Instead, they can leverage the existing infrastructure, expertise, and certified processes of a dedicated partner. This collaboration accelerates the time-to-market for new products, enabling companies to respond quickly to emerging clinical needs and opportunities. Furthermore, outsourcing production allows a brand to concentrate its resources on its core competencies, such as research and development, marketing, sales, and clinical education. A proficient Gastro Molding Consumables supplier acts as more than just a vendor; they become an integrated part of your supply chain, ensuring a consistent and reliable flow of high-quality products that carry your brand's name and reputation.

Key Considerations When Selecting a Gastro Molding Consumables Manufacturer

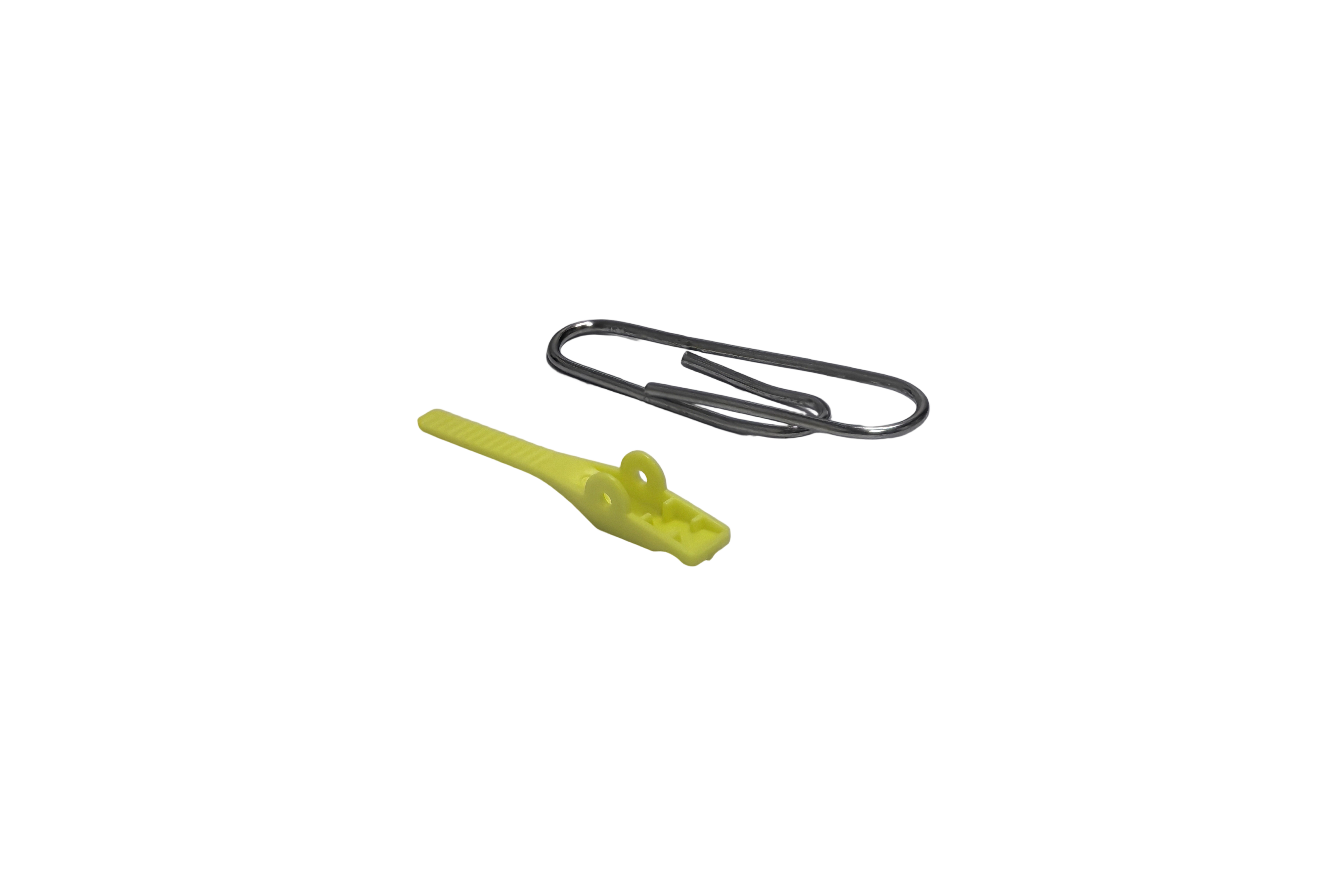

Choosing the right manufacturing partner is a critical decision that can define the success of your product line. Several key factors must be carefully evaluated to ensure the partner aligns with your quality standards and business goals. First and foremost are regulatory compliance and quality certifications. A reputable Gastro Molding Consumables manufacturer must operate under a robust quality management system, with certifications such as ISO 13485 being non-negotiable. Certifications and registrations with bodies like the FDA and CE marking for European markets demonstrate a commitment to global safety and quality standards. Material expertise is another crucial element. The partner should have deep knowledge of medical-grade polymers, their biocompatibility, chemical resistance, and suitability for various sterilization methods like EtO, gamma, or E-beam. Finally, assess their technical capabilities, including precision injection molding technology, the use of Class 100,000 or cleaner cleanrooms for assembly and packaging, and their capacity for secondary operations like ultrasonic welding, pad printing, and assembly. A partner with strong in-house engineering and design support can be invaluable in optimizing product design for manufacturability and cost-effectiveness.

The OEM Process: From Concept to Clinic

The journey of creating custom OEM Gastro Molding Consumables follows a structured and collaborative path from initial idea to a market-ready product. The process typically begins with an in-depth consultation phase where your team and the manufacturer's engineers discuss the product's intended use, functional requirements, and design specifications. This is followed by the design and development stage, where 3D models are created and refined. Once the design is finalized, the tooling and prototyping phase commences. A high-precision mold is fabricated, and initial samples are produced for functional testing, design verification, and clinical evaluation. After successful validation, the project moves into mass production. Throughout the manufacturing process, stringent quality control measures are implemented at every step to ensure each component and final product meets the agreed-upon specifications. The final stage involves packaging, sterilization, and logistics, all managed by the Gastro Molding Consumables supplier to deliver a finished, sterile product ready for distribution to clinics and hospitals worldwide. This seamless, end-to-end service ensures product integrity and quality from start to finish.

Innovations in Gastro Molding Consumables

The field of gastroenterology is constantly evolving, and the consumables used in procedures are advancing alongside it. Innovations in material science are leading to the development of devices with enhanced properties, such as improved lubricity for easier passage through endoscopes or antimicrobial coatings to reduce the risk of infection. Advanced molding techniques are enabling the creation of increasingly complex and intricate single-use devices, from multi-lumen catheters to sophisticated biopsy forceps with integrated components. There is also a growing focus on ergonomic design to reduce physician fatigue and improve procedural control, leading to better patient outcomes. A forward-thinking OEM partner is not just a fabricator but an innovation enabler, actively working with clients to incorporate these new technologies and design principles into the next generation of medical devices. By staying at the forefront of manufacturing technology, a skilled partner can help your brand pioneer new solutions that address the unmet needs of gastroenterologists.

Partnering for Success in a Competitive Market

In conclusion, the decision to work with a specialized manufacturing partner is a powerful strategy for any company looking to excel in the medical device market. The right partnership provides access to the expertise, technology, and quality systems necessary to produce superior products while allowing your company to focus on innovation and growth. When you select a partner with a proven track record, comprehensive capabilities, and an unwavering commitment to quality, you are not just outsourcing production; you are building a foundation for long-term success. Investing in a collaboration for your OEM Gastro Molding Consumables is an investment in your brand's reputation, market position, and ability to deliver exceptional tools to the healthcare professionals who depend on them every day.